Table Of Contents

Disruption to Services

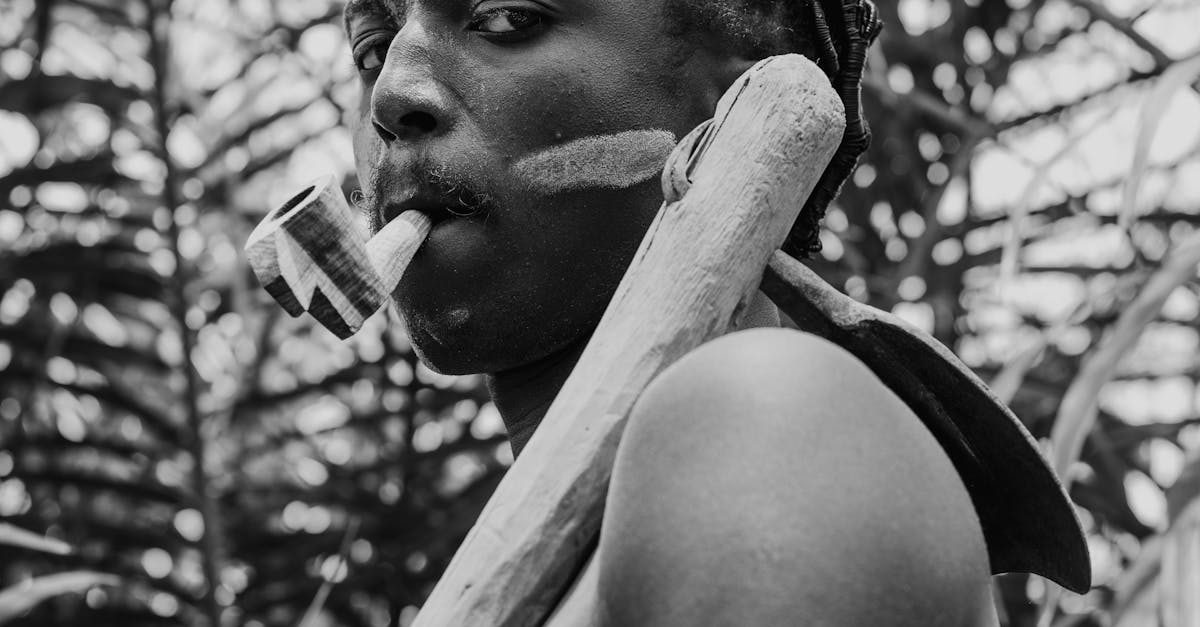

Pipe relining can lead to significant disruption in daily operations, particularly for businesses and residential properties. The process typically requires temporary restrictions on water supply and wastewater flow, which can hinder normal activities. Scheduled repairs can create uncertainty as residents and employees may need to adapt to sudden changes in their water access. This disruption can affect everything from sanitation to daily routines, leading to frustration among affected individuals.

In some cases, the disruption extends beyond immediate water and sewage services. The installation of pipe relining often necessitates the use of heavy machinery and equipment, potentially blocking access to driveways or entrances. This situation can create added inconvenience for customers or residents, especially if businesses rely heavily on foot traffic. All these factors contribute to an overall challenge for effective service delivery during the relining process.

Impact on Daily Operations

Pipe relining can lead to significant disruptions in daily operations for both residential and commercial properties. The process typically involves extensive preparation and setup, meaning that water and sewage services could be temporarily unavailable. During the relining work, businesses may need to adjust their schedules, creating inconvenience for staff and customers. Homeowners might find their access to essential facilities restricted, leading to potential frustration and interruption of regular routines.

In addition to immediate service interruptions, pipe relining may necessitate the use of heavy machinery and tools, which can create noise and further disturbance. This disruption can affect not only the property undergoing repairs but also neighbouring areas. The duration of the relining process can vary, and while it is generally quicker than traditional replacement methods, the uncertainty around completion timelines can compound the inconveniences faced by those affected.

Potential for Future Leaks

Although pipe relining presents a solution to many issues associated with aging pipes, it does not entirely eliminate the risk of future leaks. Over time, the materials used in relining can degrade due to various environmental factors, such as temperature changes and soil movement. If the underlying problems leading to leaks are not adequately addressed, the relined pipe may still become susceptible to new issues.

In addition, the relining process itself may not fully adhere to irregularities or imperfections within the existing pipe. These gaps can become potential weak points where leaks may develop later. As time passes, the combination of stress and strain on the newly lined surface can lead to further complications, making it essential for property owners to remain vigilant for signs of leaks in relined pipes.

Risks Associated with Aging Materials

As plumbing systems age, the materials used can begin to deteriorate, leading to increased risks even after pipe relining has been performed. While relining can effectively repair existing issues, it does not always address the underlying problems associated with ageing pipes. In some cases, older materials may still be susceptible to corrosion, leading to potential leaks or failures in the future.

Furthermore, the effectiveness of pipe relining may diminish if the original pipes were already compromised at the time of relining. Over time, the adhesion of the new lining material can weaken, especially if the original pipes continue to degrade. This can create a false sense of security for property owners who may believe their plumbing issues are fully resolved, exposing them to unexpected costs and further disruptions later on.

Environmental Concerns

Pipe relining is often marketed as an environmentally friendly option compared to traditional excavation methods. However, it still raises significant environmental concerns that cannot be ignored. The process involves the use of various chemicals to cure the liners, which can potentially introduce hazardous substances into the local ecosystem. If not managed properly, these chemicals may leach into the surrounding soil and waterways, posing risks to both wildlife and human health. Therefore, careful consideration and strict adherence to safety protocols are essential to mitigate these risks.

Additionally, the waste generated during the pipe relining process can contribute to environmental degradation. While the amount may be less than that produced by excavation, the disposal of old materials and excess resins still presents a challenge. Many waste management facilities are not equipped to handle these specialised materials, leading to improper disposal methods that can further harm the environment. Addressing these concerns is crucial to ensuring that the benefits of pipe relining do not come at the expense of ecological integrity.

Waste and Chemical Usage

Pipe relining often involves the use of chemicals that can pose risks to both health and the environment. The resins and other substances used in the relining process may contain volatile organic compounds (VOCs) that can release harmful emissions during application and curing. While many modern products have been developed to reduce or eliminate these emissions, concerns remain about the long-term effects of these chemicals on air quality and nearby ecosystems. Responsible handling and disposal of leftover materials are critical to mitigate these risks.

In addition to chemical concerns, the waste generated from pipe relining can be significant. While the process itself minimises the need for excavation and reduces the disruption associated with traditional methods, the materials used in relining can still contribute to landfill issues if not disposed of properly. Facilities may struggle with the disposal of unused or expired chemicals, further complicating the environmental impact. Therefore, a thorough assessment of waste management practices is essential to ensure that pipe relining is conducted sustainably.

FAQS

What is relining in the context of plumbing?

Relining is a method of repairing pipelines by inserting a new lining into the existing pipe structure, which can help to restore functionality without the need for major excavation.

What are some immediate disruptions caused by relining?

Relining can cause temporary disruptions to services such as water supply or drainage, impacting daily operations for both residential and commercial properties.

Can relining lead to future leaks?

Yes, there is a potential risk for future leaks, especially if the materials used in the relining process are not durable or if the original pipe is significantly aged and compromised.

What environmental concerns are associated with pipe relining?

Environmental concerns include the waste generated from old materials and the chemicals used in the relining process, which may pose risks to local ecosystems if not managed properly.

Is relining a cost-effective solution in the long run?

While relining may save costs in the short term by avoiding excavation, potential future leaks and the need for further repairs can make it less cost-effective over time.